-

Velocity Closed-loop

-

Pressure Closed-loop

-

Items

Data

-

Real time control scan cycle time

0.25ms

-

Velocity adjustment range

0.02~10m/s

-

Velocity adjustment stage

10 stages(with uniform acceleration function)

-

Acceleration

≥65g

-

Intensified build up stage

6 stages

-

Intensified build up time

≤ 10ms (below 1000T) ≤ 20ms (above 1000T)

-

Brake

≥45g

-

Slow velocity to high velocity position repeat accuracy

±2mm

-

Slow velocity repeat accuracy

±0.002m/s

-

High velocity repeat accuracy

±2%

-

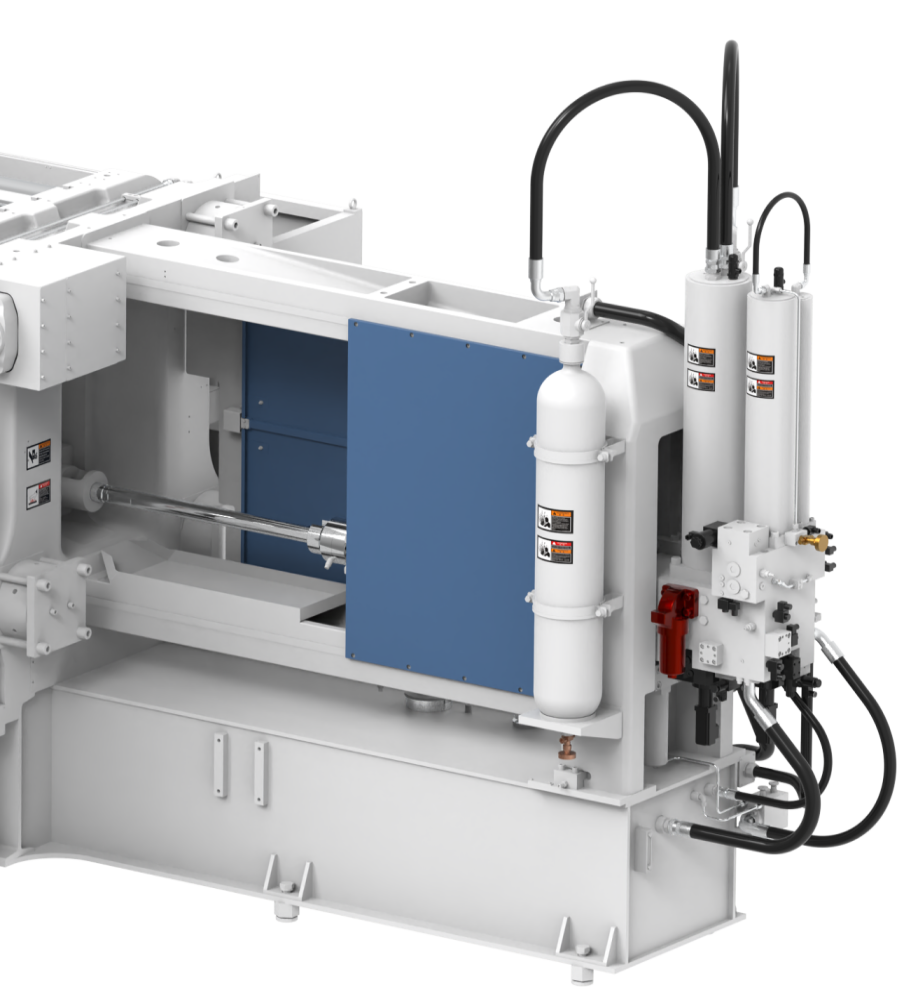

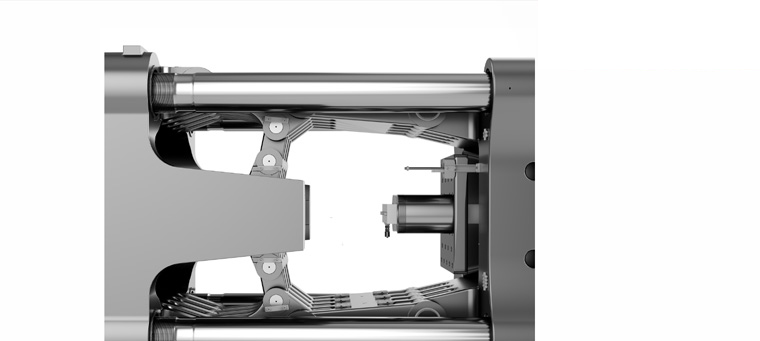

Locking mechanism

Patented toggle system and platen design.

Unique material formula and casting process.

High rigidity

-

Intelligence

Production Process Intelligent Control

Innovative and intelligent BMC Casmart 1.0-V2 production process control technology can automatically and intelligently calculate all production process parameters based on product information and display the injection process curve to help you optimize casting parameters.